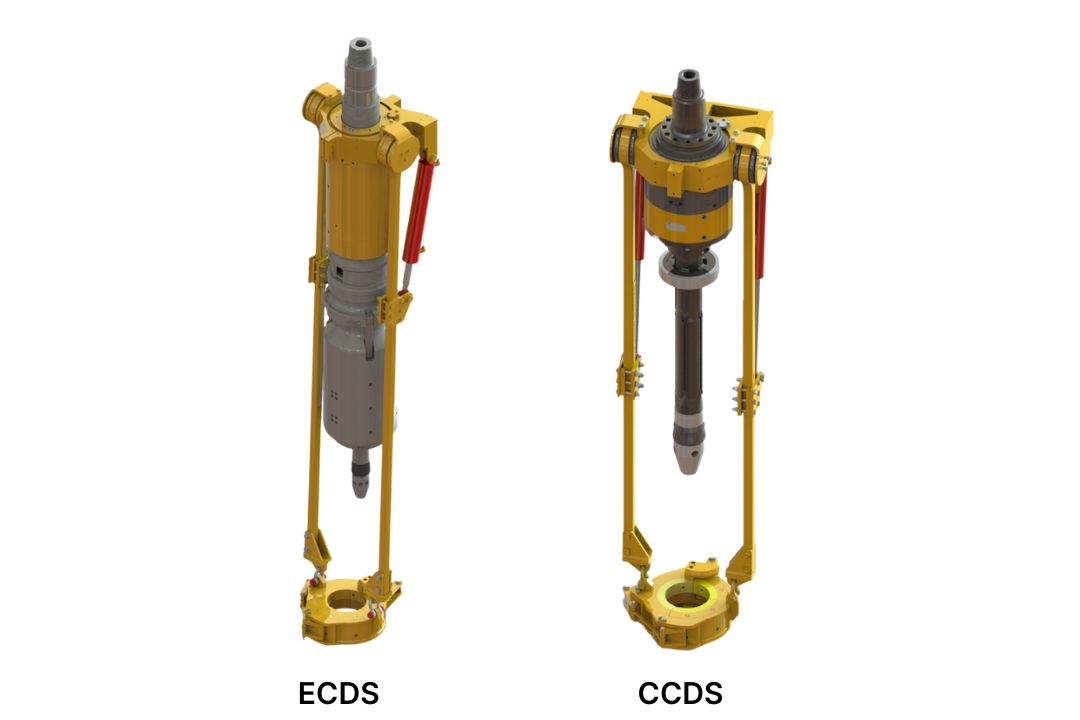

Casing Drive Systems

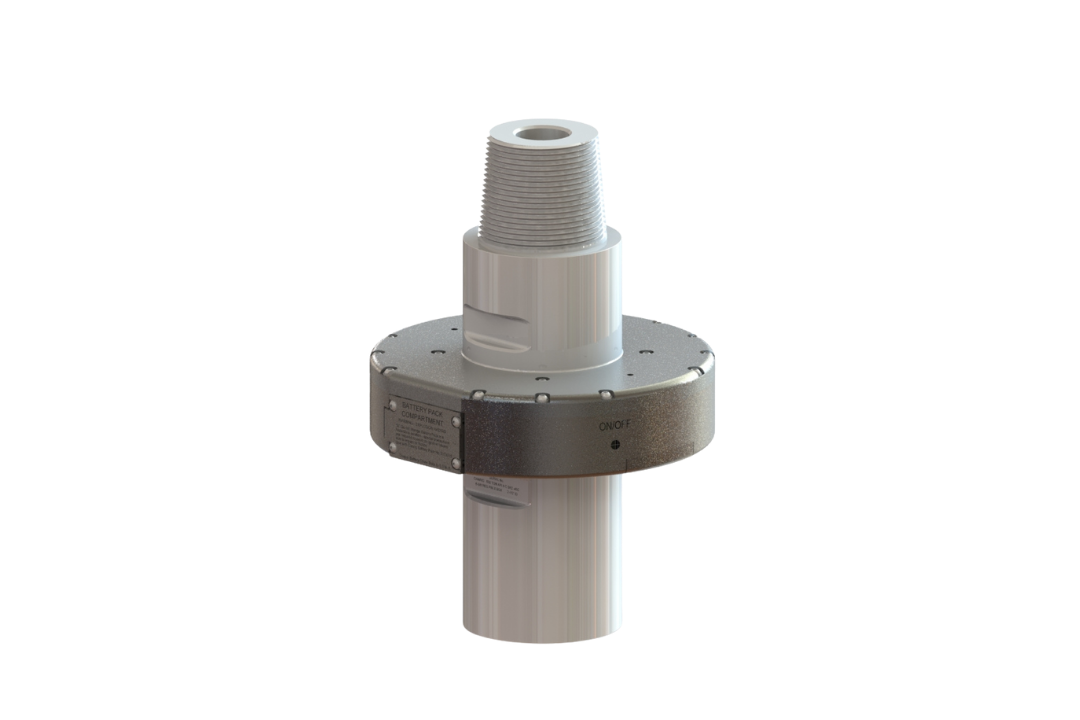

Canrig’s Casing Drive System™ (CDS) and Wireless Torque, Turn & Tension Sensor work hand-in-hand to deliver safer, faster, and more reliable casing operations. The CDS provides the mechanical capability to rotate, reciprocate, and run casing into complex wellbores, while the TesTORK® ensures every connection is made up with precision through real-time torque, turn and tension monitoring.

Together, they give operators the confidence that casing strings are properly installed, minimizing the risk while maximizing efficiency and well integrity.

Casing Drive System (CDS) Key Features:

- Field-proven slip design, patented link tilt pipe handling equipment, and a safety interlock system to maintain control of the casing

- Canrig’s global network of services provides 24/7 operational and technical support

- Provides the torque and ability to rotate and reciprocate casing to ensure it gets to the bottom

- Its compact design and light weight provide single mast rigs with safer operations and faster tubular running times

- The unit’s overall design makes it quick to rig up/down on a variety of different rig designs

- Engineered with field-proven technology for performance and serviceability

Wireless Torque, Turn & Sensor Key Features:

- Real-time monitoring of torque load applied by the top drive mitigates the need to feather connections

- Torque load is measured against both time and the number of turns for each casing connection

- Torque, tension and turn settings can be calibrated to zero onsite

- Enter connection data of torque limits, turn values and hold time for the shoulder and peak torque target for accurate and consistent makeup

Related Resources

Have questions? Our team is here to help.

Tell us more about your needs by completing the form below and a Canrig representative will contact you soon.

"*" indicates required fields